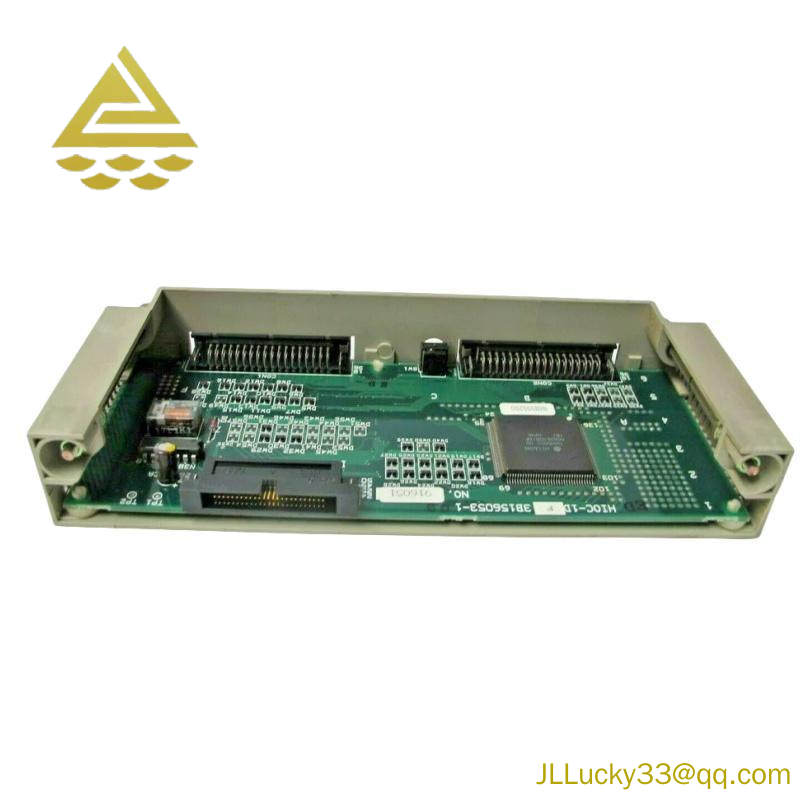

Product Overview

The A-B 1756-IR6I is a high-precision 6-channel analog input module engineered exclusively for Allen-Bradley’s ControlLogix 5000 programmable logic controller (PLC) series— a flagship platform for large-scale industrial automation, process control, and critical infrastructure requiring accurate analog signal monitoring. Designed to convert continuous analog signals from field devices (e.g., pressure transducers, temperature transmitters, flow meters, and load cells) into digital data for ControlLogix CPU processing, the A-B 1756-IR6I excels in applications where precise measurement of variable quantities is non-negotiable. Key features include multi-signal support (current/voltage), ultra-high measurement accuracy, built-in signal conditioning, and seamless integration with ControlLogix components like the A-B 1756-IB32 (digital input module) and A-B 1756-DNB (DeviceNet module). This makes the A-B 1756-IR6I indispensable for industries such as oil and gas (pipeline pressure monitoring), pharmaceutical manufacturing (temperature/flow control), and power generation (turbine vibration sensing). Compliant with global standards (e.g., IEC 61131-3, UL 508), the A-B 1756-IR6I ensures stable performance in harsh environments, minimizes measurement drift, and complements digital input systems to provide comprehensive control over mixed-signal industrial processes.

Hainan Jinlin Mechanical & Electrical is a distributor of industrial control products, specializing in a wide range of brands. We possess extensive industry knowledge and market insights. Adhering to the “Customer First, Forge Ahead” business philosophy, we provide high-quality customer service. We’re here for you, dedicated to meeting your needs!

Technical Specifications

|

Parameter

|

Value

|

|

Product Model

|

A-B 1756-IR6I

|

|

Manufacturer

|

Allen-Bradley (A-B, a Rockwell Automation brand)

|

|

Product Type

|

6-Channel Analog Input Module

|

|

Number of Input Channels

|

6 (independently configurable)

|

|

Supported Input Types

|

Current: 0-20mA DC, 4-20mA DC; Voltage: 0-10V DC, ±10V DC

|

|

Measurement Accuracy

|

±0.05% of full scale (at 25°C ±5°C); ±0.1% of full scale (over -40°C to +70°C)

|

|

Resolution

|

16 bits (4-20mA/±10V); 15 bits (0-20mA/0-10V)

|

|

Sampling Rate

|

100 samples per second (per channel); 600 samples per second (total module)

|

|

Operating Temperature Range

|

-40°C to +70°C (-40°F to +158°F)

|

|

Power Requirements

|

5V DC (from ControlLogix backplane), 0.8A max current

|

|

Mounting Type

|

ControlLogix 1756 chassis-mounted (compatible with 1756-A/B/C/D/E/F chassis)

|

|

Isolation

|

Channel-to-channel: 500V DC; Module-to-backplane: 1500V DC; Signal-to-ground: 1000V DC

|

|

Diagnostic Features

|

Open-circuit detection (for 4-20mA), overrange/underrange alerts, channel status LEDs (green = normal, yellow = warning, red = fault)

|

Key Features and Benefits

Ultra-High Accuracy for Critical Analog Measurements

The A-B 1756-IR6I delivers exceptional measurement accuracy of ±0.05% of full scale (at 25°C ±5°C)—outperforming many entry-level analog modules and ensuring reliable data capture for precision-dependent processes. For example, in pharmaceutical manufacturing, where a 0.1°C temperature deviation can ruin a batch, the module’s ability to accurately convert 4-20mA signals from RTD transmitters into precise digital values enables the ControlLogix CPU to maintain tight process control. Even across its wide operating temperature range (-40°C to +70°C), accuracy remains within ±0.1% of full scale, reducing the need for frequent calibration and eliminating errors caused by environmental fluctuations—critical for outdoor applications like oil pipeline pressure monitoring.

Multi-Signal Flexibility for Mixed-Device Integration

Unlike single-type analog modules, the A-B 1756-IR6I supports both current (0-20mA, 4-20mA) and voltage (0-10V, ±10V) inputs, with each of its 6 channels independently configurable via Allen-Bradley’s Studio 5000 software. This flexibility allows it to connect to diverse analog devices: for instance, monitoring 4-20mA signals from a flow meter (channel 1), ±10V signals from a pressure transducer (channel 2), and 0-20mA signals from a load cell (channel 3)—all on a single module. When paired with the A-B 1756-IB32 (digital input module), the A-B 1756-IR6I creates a comprehensive input system that handles both discrete (on/off) and continuous (variable) signals, simplifying system design and reducing the number of modules required in mixed-signal applications like food processing lines (where both temperature/flow analog data and sensor discrete data need monitoring).

Built-In Signal Conditioning for Noise Reduction

Industrial environments are often plagued by electromagnetic interference (EMI) from motors, variable frequency drives (VFDs), and power cables—yet the A-B 1756-IR6I mitigates this with integrated signal conditioning. The module includes low-pass filters to eliminate high-frequency noise and differential input topology to reject common-mode interference, ensuring clean signal acquisition even in noisy settings like steel mills or automotive assembly plants. For example, in a power generation facility, where EMI from turbine generators can corrupt analog signals, the A-B 1756-IR6I’s conditioning ensures accurate vibration data (from 4-20mA accelerometers) is transmitted to the ControlLogix CPU—preventing false shutdowns or equipment damage. This built-in protection eliminates the need for external signal conditioners, lowering hardware costs and simplifying wiring.

Seamless ControlLogix Ecosystem Integration

As a native ControlLogix module, the A-B 1756-IR6I integrates effortlessly with ControlLogix CPUs (e.g., A-B 1756-L82E), communication modules (e.g., A-B 1756-DNB), and digital input modules (e.g., A-B 1756-IB32). It leverages the ControlLogix backplane’s high-speed data transfer (up to 400 Mbps) to deliver analog data to the CPU in real time—critical for dynamic processes like chemical reactor temperature control, where delays in data processing could lead to unsafe conditions. The module also supports hot-swapping (when used with compatible 1756 chassis), allowing replacement without shutting down the entire system—essential for 24/7 operations like water treatment plants. Configuration via Studio 5000 further streamlines setup, as engineers can use the same software to program the CPU, set module parameters, and monitor diagnostic data.

Related Models

- A-B 1756-IR12I – 12-channel analog input variant of the A-B 1756-IR6I (ideal for large-scale systems requiring high analog channel density).

- A-B 1756-OW6I – 6-channel analog output module paired with the A-B 1756-IR6I (converts CPU digital signals to analog outputs for controlling valves, VFDs, or pumps).

- A-B 1756-IB32 – 32-channel digital input module fully compatible with the A-B 1756-IR6I (complements analog data with discrete sensor inputs for mixed-signal control).

- A-B 1756-L82E – ControlLogix 5000 CPU compatible with the A-B 1756-IR6I (processes analog data for real-time control logic and system coordination).

- A-B 1756-DNB – DeviceNet communication module paired with the A-B 1756-IR6I (enables remote deployment of the analog module in distributed I/O networks).

- A-B 1756-PA75 – Power supply module for ControlLogix chassis (delivers stable 5V DC power to the A-B 1756-IR6I and other chassis components).

Company & Service Highlights

As a certified partner of industry leaders such as Bentley Nevada, Honeywell, and Allen-Bradley (Rockwell Automation), we provide key components for discrete manufacturing, process industries, and infrastructure. We offer a one-year warranty on the A-B 1756-IR6I and all industrial control products, ensuring peace of mind for our customers. Our pre-sales team specializes in ControlLogix mixed-signal system design—helping you confirm compatibility with your analog devices (e.g., transmitters, load cells), calculate channel requirements, and integrate the module with existing components like the A-B 1756-IB32. Our after-sales service includes support for calibration, diagnostic troubleshooting (e.g., resolving open-circuit faults in 4-20mA loops), and firmware updates—critical for maintaining the module’s high accuracy and reliability.

If you cannot find the model you need (e.g., other Allen-Bradley ControlLogix analog modules or parts from GE/TRICONEX), please contact us immediately.

Contact Information

- WhatsApp: [https://wa.me/+86 19389860630]

- Email: jllucky33@qq.com

Leave a comment

Your email address will not be published. Required fields are marked *