BY

jonson

IN

Company News

TURCK BL20-16DI-24VDC-P | Modular Digital Input I/O Module

Product Overview

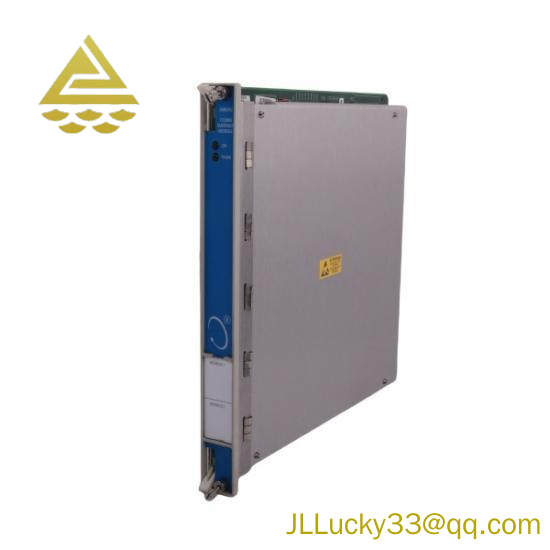

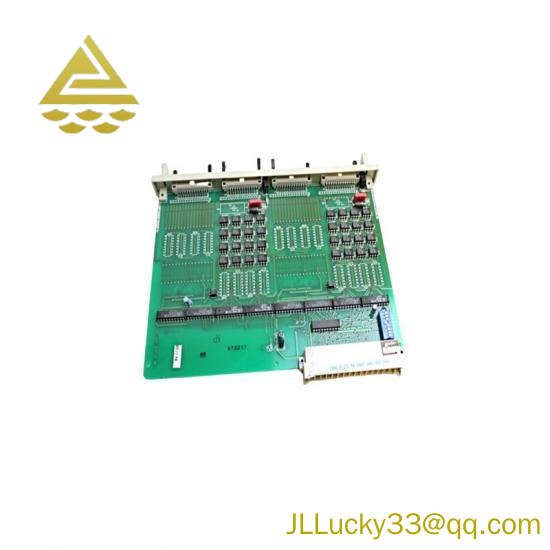

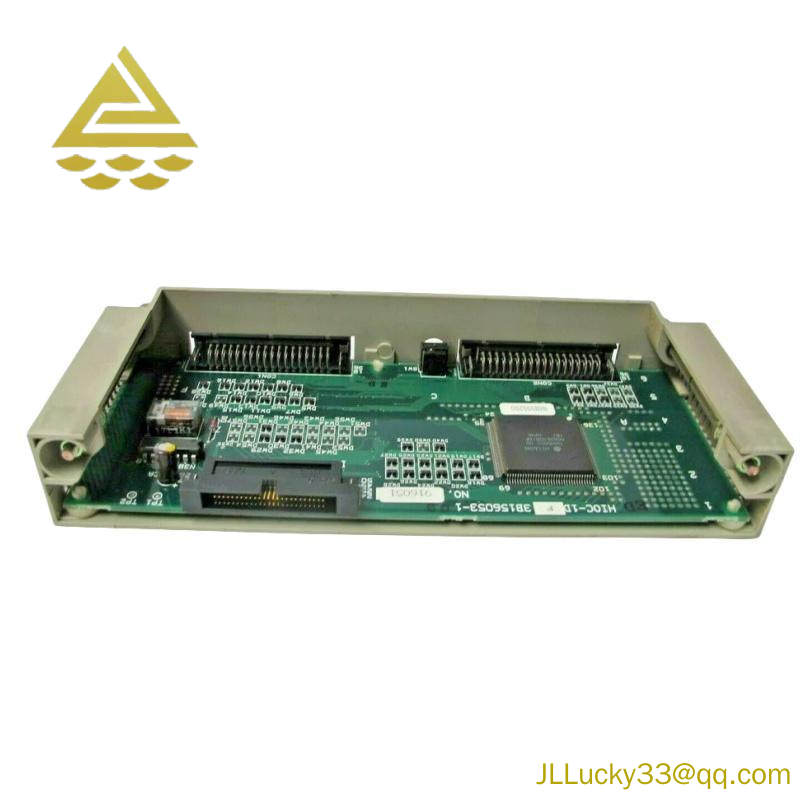

The TURCK BL20-16DI-24VDC-P is a high-performance digital input module engineered by TURCK— a global leader in industrial automation and connectivity solutions—for seamless integration into distributed control systems (DCS) and programmable logic controller (PLC) networks. Designed specifically to monitor discrete 24V DC signals in harsh industrial environments, the TURCK BL20-16DI-24VDC-P offers 16 independent input channels, enabling simultaneous monitoring of multiple devices such as limit switches, proximity sensors, and pushbuttons. Key features include robust protection against electrical interference, compact design for space-constrained control cabinets, and compatibility with TURCK’s BL20 modular I/O system—making it a versatile choice for sectors like automotive manufacturing, material handling, and process industries. As a core component of TURCK’s decentralized I/O lineup, the TURCK BL20-16DI-24VDC-P ensures reliable signal acquisition, reduces wiring complexity, and supports real-time data transmission to central control systems—critical for maintaining operational efficiency and minimizing downtime. Whether deployed in assembly lines, conveyor systems, or industrial machinery, the TURCK BL20-16DI-24VDC-P delivers consistent performance under demanding conditions.

Hainan Jinlin Mechanical & Electrical is a distributor of industrial control products, specializing in a wide range of brands. We possess extensive industry knowledge and market insights. Adhering to the “Customer First, Forge Ahead” business philosophy, we provide high-quality customer service. We’re here for you, dedicated to meeting your needs!

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | TURCK BL20-16DI-24VDC-P |

| Manufacturer | TURCK |

| Product Type | Modular Digital Input I/O Module |

| Number of Input Channels | 16 (independent, configurable) |

| Input Voltage Range | 19.2 V DC to 30 V DC |

| Input Current | 2.5 mA typical (at 24 V DC) |

| Signal Response Time | < 1 ms (for fast event detection) |

| Communication Protocol | PROFINET; optional support for Modbus TCP/IP, EtherNet/IP |

| Protection Features | Short-circuit protection (per channel); ESD protection (IEC 61000-4-2, ±8 kV contact/±15 kV air) |

| Operating Temperature | -25°C to +60°C (-13°F to +140°F) |

| Mounting Type | DIN rail (35 mm, EN 50022 standard) |

| Dimensions (W x H x D) | 12.5 mm x 100 mm x 120 mm |

Key Features and Benefits

High Channel Density and Space Efficiency

The TURCK BL20-16DI-24VDC-P packs 16 digital input channels into a ultra-compact 12.5 mm-wide housing—significantly reducing the space required in control cabinets compared to traditional I/O modules. This high channel density is ideal for applications like automotive assembly lines or material handling systems, where dozens of sensors (e.g., photoelectric sensors, limit switches) need to be connected but cabinet space is limited. The modular design also allows easy expansion: users can daisy-chain multiple TURCK BL20-16DI-24VDC-P modules or pair them with TURCK’s BL20 digital output/analog modules to create a customized I/O solution, eliminating the need for bulky, fixed-function control units.

Robust Protection for Harsh Industrial Environments

Built to withstand the electrical noise and physical stress of industrial settings, the TURCK BL20-16DI-24VDC-P includes multiple layers of protection. Each input channel features short-circuit protection, preventing damage to the module if a sensor wire is accidentally grounded or shorted—critical for reducing maintenance costs and unplanned downtime. The module also meets strict ESD (IEC 61000-4-2) and surge (IEC 61000-4-5) protection standards, ensuring reliable operation in environments with high electromagnetic interference (EMI), such as near large motors or welding equipment. Additionally, its wide operating temperature range (-25°C to +60°C) allows deployment in cold storage facilities, outdoor enclosures, or heated manufacturing areas without performance degradation.

Fast Response and Real-Time Data Transmission

With a signal response time of less than 1 ms, the TURCK BL20-16DI-24VDC-P captures fast-changing discrete signals—such as the position of a high-speed conveyor belt or the actuation of a precision valve—without delay. This speed is essential for time-critical applications like packaging machinery or automated sorting systems, where even a 10-ms lag could cause product jams or processing errors. The module leverages PROFINET (with optional support for Modbus TCP/IP and EtherNet/IP) for high-speed communication with central PLCs/DCS, enabling real-time data transfer and remote monitoring. Users can also access diagnostic data (e.g., channel status, voltage levels) via the protocol, allowing proactive identification of issues like faulty sensors or loose wiring before they cause system failures.

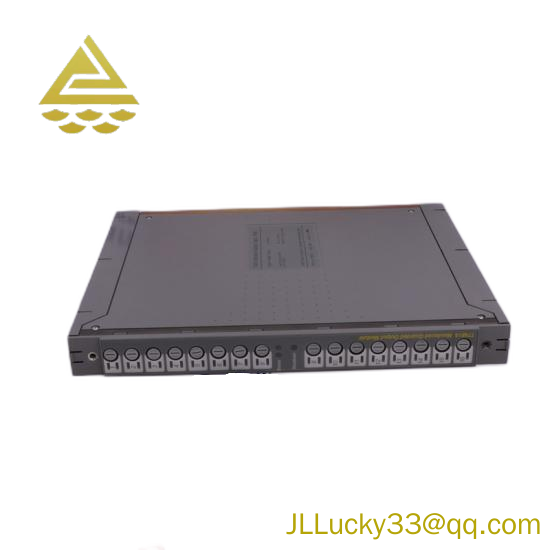

Easy Installation and Configuration

The TURCK BL20-16DI-24VDC-P simplifies setup with tool-free DIN rail mounting and pluggable terminal blocks for sensor wiring—reducing installation time by up to 50% compared to hardwired modules. The pluggable terminals also make it easy to replace the module without rewiring, minimizing downtime during maintenance. Configuration is equally straightforward: users can set input parameters (e.g., signal filtering, edge detection) via TURCK’s Turck ToolSuite software or directly through the PLC’s programming environment (e.g., Siemens TIA Portal, Rockwell Studio 5000). This compatibility with industry-standard software ensures the TURCK BL20-16DI-24VDC-P integrates seamlessly into existing workflows, no specialized training required.

Related Models

- TURCK BL20-16DI-24VDC-PN – Enhanced variant of the TURCK BL20-16DI-24VDC-P with advanced PROFINET features (e.g.,IRT for isochronous real-time communication) for high-speed, time-sensitive applications.

- TURCK BL20-8DI-24VDC-P – Compact 8-channel version of the TURCK BL20-16DI-24VDC-P, ideal for low-density sensor applications (e.g., small machinery) where 16 channels are unnecessary.

- TURCK BL20-16DO-24VDC-0.5A-P – Complementary digital output module, designed to work with the TURCK BL20-16DI-24VDC-P to control actuators (e.g., solenoids, relays) in the same BL20 I/O network.

- TURCK BL20-16DI-24VDC-P-EX – Explosion-proof certified model of the TURCK BL20-16DI-24VDC-P, compliant with ATEX/IECEx Zone 2 for use in hazardous areas (e.g., chemical plants, oil refineries).

- TURCK BL20-16DI-12VDC-P – 12V DC input variant of the TURCK BL20-16DI-24VDC-P, optimized for low-voltage sensor networks (e.g., mobile robotics, battery-powered equipment).

- TURCK BL20-GW-PROFINET – Gateway module for the TURCK BL20-16DI-24VDC-P, enabling integration into non-PROFINET networks (e.g., DeviceNet, CANopen) for legacy system retrofits.

- TURCK BL20-16DI-24VDC-P-HD – High-density stacked variant of the TURCK BL20-16DI-24VDC-P, allowing vertical mounting of two modules in the space of one for extreme cabinet space savings.

Company & Application Highlights

As a certified partner of industry leaders (including TURCK for industrial connectivity solutions), we provide critical I/O components for automation-driven sectors:

- Automotive Manufacturing: Supporting assembly lines with the TURCK BL20-16DI-24VDC-P for monitoring proximity sensors (e.g., part presence detectors) and limit switches, ensuring precise control of robotic arms and conveyor systems.

- Material Handling: Supplying the TURCK BL20-16DI-24VDC-P for warehouse automation (e.g., automated guided vehicles/AGVs, conveyor sorters) to track sensor signals in real time, optimizing throughput and reducing errors.

- Process Industries: Delivering the TURCK BL20-16DI-24VDC-P (and its explosion-proof variant) for petrochemical and pharmaceutical plants, where its robust protection and reliable communication ensure compliance with safety standards and process stability.

We prioritize pre-sales expertise (e.g., verifying compatibility of the TURCK BL20-16DI-24VDC-P with your PLC/DCS and sensor network) and after-sales support, including a one-year warranty on all TURCK products. If you cannot find the exact I/O module or need help designing a custom BL20 system, please contact us immediately.