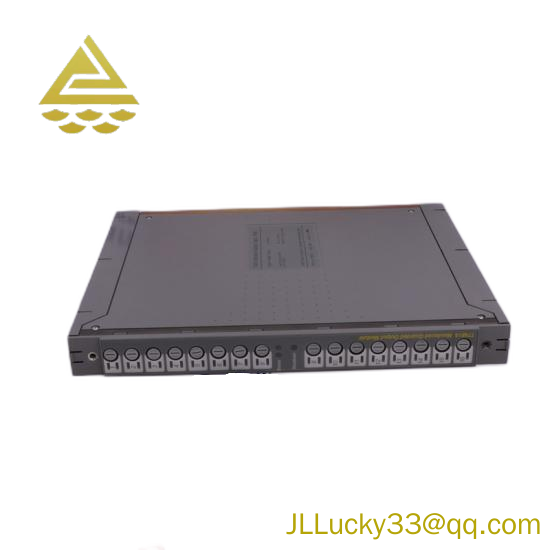

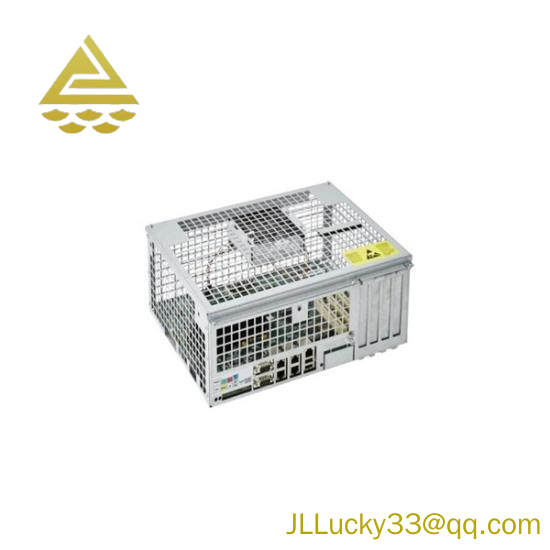

Product Overview

The FIRE NXF4000 is a high-performance fire safety control module designed to serve as the core interface for industrial fire detection and suppression systems, ideal for sectors where rapid fire response is critical to protecting personnel, equipment, and operations. As a dedicated fire safety component, the FIRE NXF4000 excels at integrating signals from fire detectors (e.g., smoke, heat, flame sensors) and triggering coordinated responses—such as activating sprinkler systems, sounding alarms, or initiating emergency shutdowns (ESD) in sync with industrial safety instrumented systems (SIS). Key features of the FIRE NXF4000 include EN 54 certification (global standard for fire detection equipment), multi-zone monitoring capabilities, and real-time fault diagnostics—making it ideal for mission-critical applications like petrochemical refineries, power plant turbine halls, warehouse storage facilities, and chemical processing plants. Whether managing small-scale fire zones or large, distributed fire safety networks, the FIRE NXF4000 ensures fast response times, reduces false alarms, and adheres to strict fire safety regulations. Its rugged construction resists dust, humidity, and temperature extremes, solidifying its position as a reliable fire safety solution for harsh industrial environments.

Hainan Jinlin Mechanical & Electrical is a distributor of industrial control products, specializing in a wide range of brands. We possess extensive industry knowledge and market insights. Adhering to the “Customer First, Forge Ahead” business philosophy, we provide high-quality customer service. We’re here for you, dedicated to meeting your needs!

Technical Specifications

|

Parameter

|

Value

|

|

Product Model

|

FIRE NXF4000

|

|

Manufacturer

|

FIRE (Fire Safety Systems)

|

|

Product Type

|

Industrial Fire Safety Control Module

|

|

Monitoring Zones

|

8 configurable fire detection zones

|

|

Input Compatibility

|

4-20 mA analog fire detectors; dry-contact smoke/heat sensors

|

|

Output Capabilities

|

6 relay outputs (for alarms, sprinklers, ESD triggers); 2 digital outputs

|

|

Safety Certification

|

EN 54-17 (fire control panels); UL 864 (US fire safety standard)

|

|

Operating Voltage

|

24 V DC (20-30 V DC range)

|

|

Operating Temperature

|

-10°C to +55°C (14°F to +131°F)

|

|

Response Time

|

≤ 200 ms (detector signal to output activation)

|

|

IP Rating

|

IP30 (panel-mounted, for control cabinets); IP54 (with optional weatherproof enclosure)

|

Key Features and Benefits

EN 54 & UL 864 Certification for Global Compliance

The FIRE NXF4000 is fully certified to EN 54-17 (European standard for fire control modules) and UL 864 (US standard for fire alarm control units), ensuring compliance with global fire safety regulations. This certification validates that the module meets strict performance criteria—including reliable signal processing, resistance to environmental stress, and fail-safe operation—critical for industries operating across regions (e.g., multinational petrochemical companies). Unlike non-certified fire control modules, the FIRE NXF4000 undergoes independent testing to confirm it can trigger timely responses to real fire events while minimizing false alarms, giving facility managers confidence in their fire safety infrastructure.

Multi-Zone Monitoring for Targeted Response

With 8 configurable fire detection zones, the FIRE NXF4000 enables granular monitoring of large facilities—allowing operators to identify the exact location of a fire event and deploy targeted responses. For example, in a refinery, a fire in Zone 3 (tank storage) can trigger sprinklers in that zone only, while sounding alarms and initiating ESD for adjacent equipment—reducing unnecessary operational disruption. Each zone supports multiple detectors (e.g., 10 smoke sensors per zone), and the module provides zone-specific status updates via a local LCD display or remote HMI, ensuring clear visibility into fire safety status at all times.

Seamless Integration with Industrial Safety Systems

The FIRE NXF4000 is designed to integrate with industrial safety instrumented systems (SIS) and emergency shutdown (ESD) networks—critical for process industries where fire events require coordinated equipment shutdowns. It supports communication protocols such as Modbus RTU/TCP and OPC UA, enabling data sharing with SIS controllers (e.g., HIMA H41q, Honeywell Safety Manager) and SCADA systems. This integration ensures that a fire detected by the FIRE NXF4000 can trigger immediate ESD actions (e.g., closing fuel valves, shutting down pumps) to prevent fire spread, aligning fire safety with broader process safety goals. Additionally, the module’s relay outputs can directly activate on-site alarms, emergency lighting, and evacuation systems—creating a unified safety response.

Advanced Diagnostics for Preventive Maintenance

The FIRE NXF4000 features built-in real-time diagnostics that monitor detector health, wiring integrity, and module power supply. If a fault is detected (e.g., a disconnected smoke sensor, short circuit in wiring, or low power), the module immediately alerts operators via a local alarm, LCD error code, and remote notification (e.g., email, SMS). It also logs fault history for up to 1,000 events, enabling technicians to identify recurring issues (e.g., frequent detector failures in a dusty zone) and implement preventive maintenance. This proactive approach reduces unplanned downtime for fire safety systems and ensures the FIRE NXF4000 remains operational when needed most.

Rugged Design for Industrial Environments

Engineered for harsh industrial settings, the FIRE NXF4000 operates reliably across a temperature range of -10°C to +55°C and features an IP30 rating (with optional IP54 weatherproof enclosure) for protection against dust and water ingress. It includes surge protection (per IEC 61000-4-5) to resist electrical spikes from nearby equipment and EMI shielding to prevent interference from industrial motors or power lines—critical for maintaining signal integrity in noisy environments (e.g., steel mills, power plants). The module’s durable metal chassis and vibration-resistant components (per IEC 60068-2-6) ensure long-term performance, even in facilities with heavy machinery.

Warranty and Expert Support

Hainan Jinlin provides a one-year warranty for the FIRE NXF4000, covering defects in materials and workmanship. Our pre-sales team—with specialized expertise in industrial fire safety—offers technical consultations to verify that the FIRE NXF4000 matches your facility’s zone count, detector type (analog/dry-contact), and integration needs (e.g., Modbus vs. OPC UA). Post-sales support includes remote troubleshooting (via secure Modbus connection) and expedited replacement services, ensuring minimal downtime for your fire safety system.

Related Models

- FIRE NXF3000 – Compact version of the FIRE NXF4000; 4 fire detection zones, ideal for small facilities (e.g., warehouse storage units, small chemical plants).

- FIRE NXF5000 – High-capacity upgrade of the FIRE NXF4000; 16 fire detection zones + Ethernet connectivity, designed for large-scale facilities (e.g., power plants, refineries).

- FIRE D1000 – Analog fire detector; paired with the FIRE NXF4000 for smoke/heat detection in harsh zones (e.g., high-temperature turbine halls).

- FIRE R2000 – Relay expansion module; adds 8 additional relay outputs to the FIRE NXF4000 for controlling more fire suppression systems (e.g., foam systems, gas extinguishers).

- FIRE C3000 – Communication gateway; enables the FIRE NXF4000 to integrate with legacy SIS systems (e.g., older Honeywell SIS) via proprietary protocols.

- FIRE HMI500 – Remote human-machine interface; provides real-time zone status, fault alerts, and manual control for the FIRE NXF4000 in control rooms.

- FIRE E100 – Power supply backup module; ensures the FIRE NXF4000 remains operational during main power outages, with 4 hours of backup runtime.

Company & Application Highlights

As a certified partner of industry leaders such as FIRE, HIMA, and Honeywell, we provide key components for critical sectors:

- Process Industries: Fire safety systems in oil & gas, petrochemical, and chemical plants—where the FIRE NXF4000 monitors fire risks in tank storage, processing units, and turbine halls, integrating with ESD systems to prevent disaster.

- Discrete Manufacturing: Fire safety for automotive assembly plants and aerospace facilities—using the FIRE NXF4000 to monitor paint booths, welding areas, and warehouse storage, triggering alarms and evacuation systems.

- Infrastructure: Fire safety for power plants (coal, gas, nuclear) and wastewater treatment facilities—relying on the FIRE NXF4000’s rugged design and multi-zone monitoring to protect critical infrastructure and personnel.

Our pre-sales team offers personalized guidance to confirm FIRE NXF4000 compatibility with your detector types and safety system integration needs, while post-sales support includes technical troubleshooting and a one-year warranty. If you cannot find the model you need (or require custom fire safety configurations), contact us immediately.

Contact Information