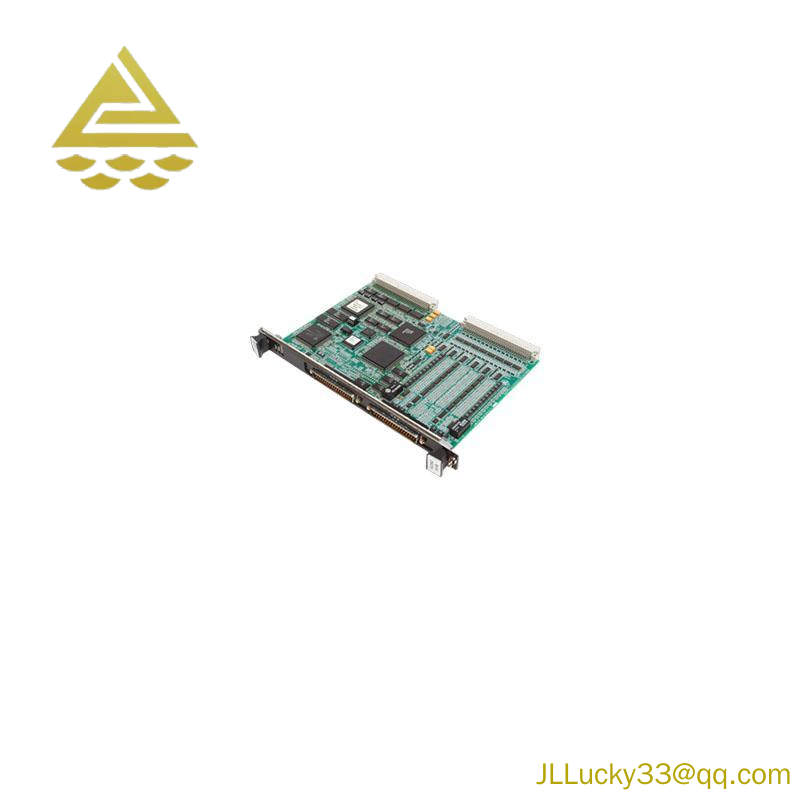

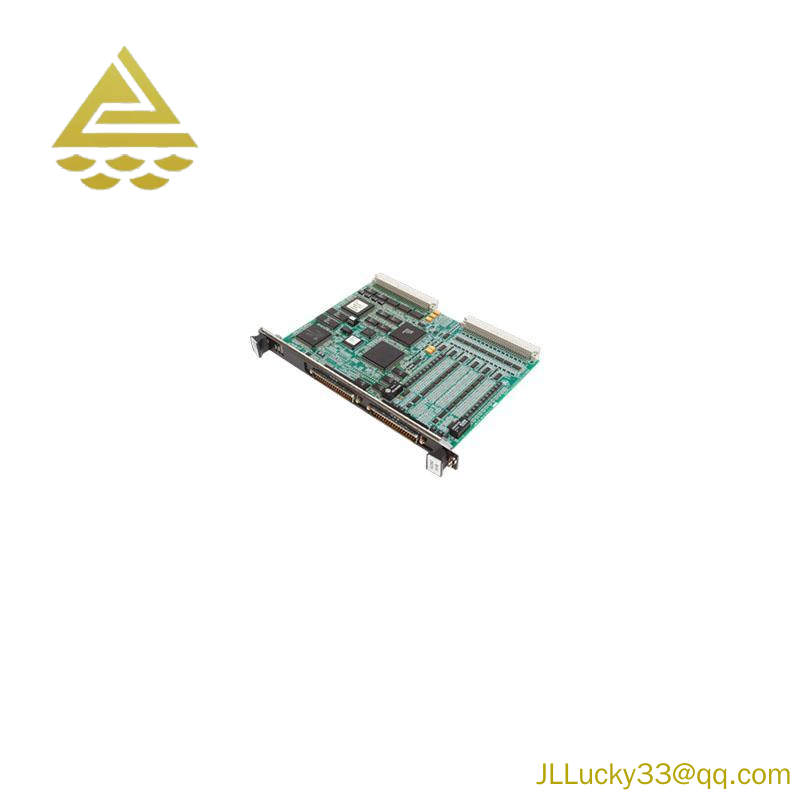

LXM23AU75M3X | Servo Drive / Motion Controller

Product Overview

The Schneider LXM23AU75M3X is a high-performance servo drive system designed for precise motor control in demanding industrial automation applications. Part of Schneider Electric’s Lexium 23 series, the LXM23AU75M3X combines compact design, robust construction, and advanced control algorithms to ensure smooth and accurate motion control. It is ideal for CNC machines, packaging lines, robotics, and other machinery requiring precise positioning and speed regulation.

The LXM23AU75M3X delivers high dynamic response and torque control, enabling consistent operation even under varying loads. Its versatile connectivity allows seamless integration with Schneider Electric PLCs, HMIs, and other automation components. The drive features built-in safety functions, thermal protection, and diagnostic capabilities, enhancing operational reliability and minimizing downtime.

Hainan Jinlin Mechanical & Electrical provides genuine LXM23AU75M3X units with professional pre-sales and after-sales support. Every unit comes with a one-year warranty, ensuring reliable performance and peace of mind for your automation projects. Our team offers expert guidance for installation, configuration, and maintenance, guaranteeing optimal system performance.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | LXM23AU75M3X |

| Manufacturer | Schneider Electric |

| Product Type | Servo Drive / Motion Controller |

| Rated Power | 750 W |

| Input Voltage | 230 V AC |

| Control Mode | Position / Speed / Torque |

| Communication Protocol | Modbus, CANopen |

| Ambient Temperature | 0°C to 50°C |

| Mounting | Panel / DIN rail |

| IP Rating | IP20 |

Key Features and Benefits

High-Precision Motion Control

The LXM23AU75M3X utilizes advanced servo control algorithms to deliver precise position, speed, and torque management. Its dynamic response and smooth acceleration/deceleration ensure optimal performance for high-speed and high-accuracy applications.

Robust Safety and Reliability

Equipped with thermal protection, overload detection, and fault diagnostics, the LXM23AU75M3X safeguards both the motor and drive system. Built-in safety functions minimize risks during operation, increasing equipment uptime and reliability.

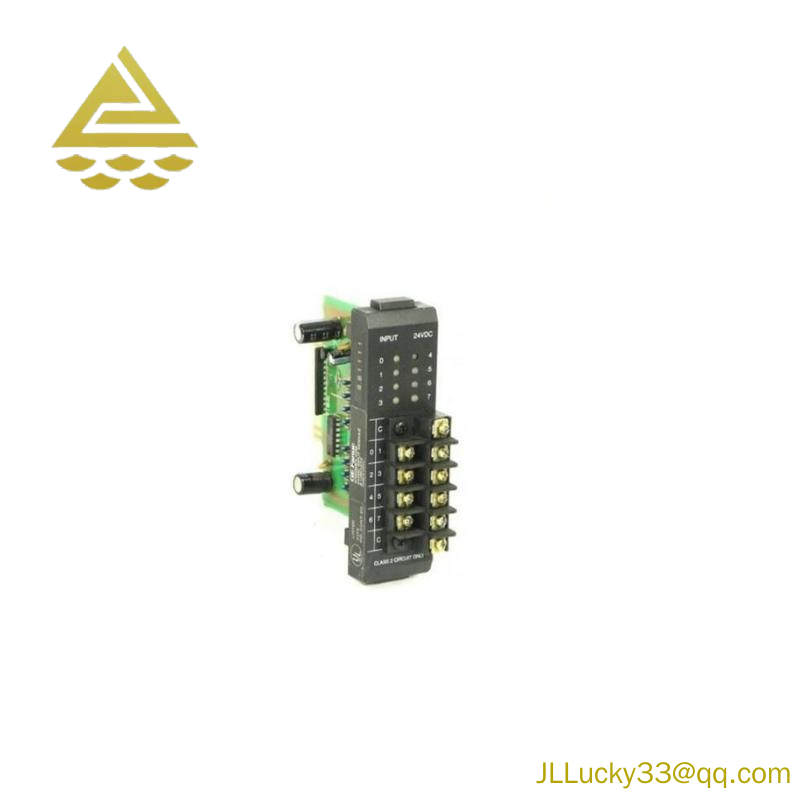

Flexible Connectivity and Integration

This drive supports Modbus and CANopen communication, allowing seamless integration with PLCs, HMIs, and other control devices. It simplifies system configuration and enables real-time monitoring and predictive maintenance.

Compact and Easy Installation

The LXM23AU75M3X features a compact footprint suitable for panel or DIN rail mounting. Its intuitive interface and configuration software reduce setup time and facilitate fast commissioning in diverse industrial environments.

Durability in Industrial Environments

Designed for rigorous industrial applications, the LXM23AU75M3X operates reliably across a temperature range of 0°C to 50°C. Its IP20 rating and solid construction ensure long-term operational stability with minimal maintenance.

Related Models

-

LXM23AU75M3B – Variant with alternative mounting options

-

LXM23AU37M3X – Lower power 370 W version for smaller applications

-

LXM23AU100M3X – Higher power 1 kW version for larger machinery

-

LXM23AP75M3X – Servo drive with advanced programming features

-

LXM23AU75M3Y – Enhanced model with extended connectivity options

-

LXM23AU150M3X – 1.5 kW model for heavy-duty applications

-

LXM23AU75M3R – Replacement model compatible with existing Lexium 23 systems