Product Overview

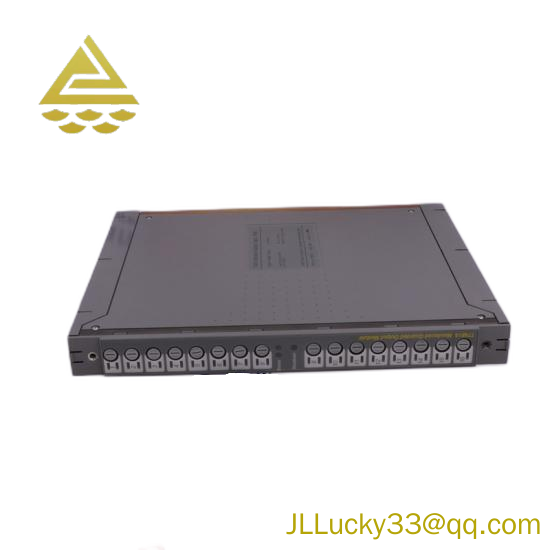

The FIRE FX5019 Module is a high-performance industrial control module designed for demanding automation applications, serving as a reliable interface for signal processing and control in industrial systems such as distributed control systems (DCS) and machine automation setups. It is engineered to deliver stable and precise operation in sectors where operational efficiency and system reliability are paramount, including automotive manufacturing, food and beverage processing, and heavy machinery industries. Core features of the FIRE FX5019 Module include multi-channel digital I/O support, high-speed signal processing, compatibility with industry-standard communication protocols, and a rugged design that withstands harsh industrial conditions. With its ability to seamlessly integrate with various industrial controllers and sensors, the FIRE FX5019 Module ensures smooth data exchange and accurate control execution, minimizing operational disruptions. Its user-friendly configuration and low maintenance requirements further enhance its practicality, making the FIRE FX5019 Module a preferred choice for industrial automation professionals seeking high-quality control solutions.

Hainan Jinlin Mechanical & Electrical is a distributor of industrial control products, specializing in a wide range of brands. We possess extensive industry knowledge and market insights. Adhering to the “Customer First, Forge Ahead” business philosophy, we provide high-quality customer service. We’re here for you, dedicated to meeting your needs!

Technical Specifications

|

Parameter

|

Value

|

|

Product Model

|

FIRE FX5019 Module

|

|

Manufacturer

|

FIRE

|

|

Product Type

|

Industrial Digital I/O Control Module

|

|

Digital I/O Channels

|

16 digital input channels, 16 digital output channels

|

|

Input Voltage Range

|

12 – 24 V DC (sinking/sourcing)

|

|

Output Current Capacity

|

2 A per channel (max), 10 A total per module

|

|

Communication Protocols

|

Modbus RTU, Ethernet/IP, PROFINET

|

|

Operating Temperature

|

-15°C to +70°C (5°F to +158°F)

|

|

Power Supply

|

24 V DC (±15%)

|

|

Power Consumption

|

8 W (typical), 12 W (max)

|

|

Mounting Type

|

DIN rail-mounted (35 mm standard)

|

|

IP Rating

|

IP20 (front panel), IP40 (module body)

|

Key Features and Benefits

Versatile Digital I/O Configuration

The FIRE FX5019 Module comes equipped with 16 digital input and 16 digital output channels, offering flexible configuration to meet diverse industrial control needs. The input channels support both sinking and sourcing modes, compatible with a wide range of industrial sensors (such as photoelectric sensors, limit switches, and proximity sensors), while the output channels can drive various actuators like relays, solenoid valves, and small motors. This versatility eliminates the need for multiple single-function modules, reducing system complexity and installation costs. For example, in an automotive assembly line, the module can simultaneously monitor the position of conveyor belts (via input channels) and control the activation of robotic arms (via output channels), streamlining the entire production process.

High-Speed Signal Processing and Response

With a signal processing speed of up to 1 ms per channel, the FIRE FX5019 Module ensures rapid detection and response to changes in input signals—critical for time-sensitive applications like packaging machinery or high-speed assembly lines. The module’s output channels also feature fast switching times (less than 0.5 ms), enabling quick actuation of devices to maintain production 节奏 and prevent product defects. Additionally, the module incorporates advanced signal filtering technology to reduce noise interference from nearby electrical equipment, ensuring accurate signal detection even in high-electromagnetic-interference (EMI) environments, such as metalworking facilities with large motors.

Multi-Protocol Communication for Seamless Integration

The FIRE FX5019 Module supports three widely used industrial communication protocols: Modbus RTU (for serial communication with legacy controllers), Ethernet/IP (for integration with Rockwell Automation systems), and PROFINET (for real-time communication with Siemens and other PROFINET-compatible automation devices). This multi-protocol support allows the module to easily connect to existing industrial networks without the need for additional converters, simplifying system upgrades and retrofits. For instance, in a food processing plant, the module can communicate with a Siemens DCS via PROFINET to transmit data on temperature sensor inputs and receive commands to control refrigeration unit outputs, ensuring compliance with food safety regulations.

Rugged Design for Harsh Industrial Environments

Built to endure the rigors of industrial operations, the FIRE FX5019 Module features a durable plastic housing with an IP40 rating for the module body (protecting against dust and splashing water) and an IP20 rating for the front panel (suitable for control cabinet installations). It operates reliably in a wide temperature range (-15°C to +70°C), making it suitable for both cold storage facilities and high-temperature environments like glass manufacturing plants. The module also withstands vibration (up to 50 Hz, 10 g acceleration) and shock (up to 50 g, 11 ms duration), ensuring stable performance in mobile equipment or facilities with heavy machinery. Its long operational lifespan (average 10+ years) and low failure rate (MTBF of 1,200,000 hours) further reduce maintenance costs and downtime.

User-Friendly Configuration and Diagnostics

Configuring the FIRE FX5019 Module is straightforward using FIRE’s dedicated configuration software, which offers a graphical interface for setting up I/O parameters, communication protocols, and alarm thresholds. The software also allows users to save and load configuration files, simplifying the deployment of multiple modules in the same application. For maintenance, the module provides comprehensive diagnostic functions: local LED indicators on the front panel display the status of each I/O channel (active, fault, or off) and communication link (connected/disconnected), enabling quick on-site troubleshooting. Remote diagnostics via the communication network also allow maintenance teams to monitor module health, view input/output status, and reset faults without accessing the physical module—saving time and improving operational efficiency.

Related Models

- FIRE FX5020 Module – Upgraded version of the FIRE FX5019 Module with 32 digital I/O channels (16 input, 16 output) and added support for BACnet protocol, ideal for large-scale building automation and industrial control systems.

- FIRE FX5018 Module – Previous-generation digital I/O module with 8 input and 8 output channels, suitable for small-scale applications like standalone machine control.

- FIRE FX5021 Module – Analog I/O module compatible with the FIRE FX5019 Module, offering 8 analog input and 4 analog output channels for monitoring and controlling continuous variables (e.g., temperature, pressure).

- FIRE FX5019-T Module – Temperature-resistant variant of the FIRE FX5019 Module, operating up to +85°C for high-temperature applications like steel manufacturing.

- FIRE FX5019-R Module – Redundant version of the FIRE FX5019 Module with dual power supplies and communication ports, designed for safety-critical applications like power plant control systems.

- FIRE FX5022 Module – Mixed I/O module that combines 8 digital I/O channels (from the FIRE FX5019 Module design) and 4 analog I/O channels, suitable for applications requiring both discrete and continuous control.

- FIRE FX5019-W Module – Weatherproof version of the FIRE FX5019 Module with an IP65 rating, designed for outdoor installations like solar power plant monitoring or outdoor conveyor systems.

Company Service & Application Areas

As a certified partner of industry leaders including FIRE, Bentley Nevada, and Honeywell, we provide key components for critical sectors:

- Discrete Manufacturing: Control system integration for automotive assembly lines, packaging machinery, and electronic component manufacturing (e.g., using the FIRE FX5019 Module to monitor sensor inputs and control robotic actuators).

- Process Industries: I/O control for food and beverage processing, chemical manufacturing, and pharmaceutical production (e.g., using the module to manage valve actuation and tank level monitoring via digital signals).

- Infrastructure: Automation for water treatment plants, wastewater management systems, and renewable energy facilities (e.g., using the FIRE FX5019 Module to control pump operation and monitor flow meter inputs).

- Heavy Machinery: Control solutions for construction equipment, mining machinery, and agricultural vehicles (e.g., using the module’s rugged design to withstand vibration and extreme temperatures in off-road environments).

We offer a one-year warranty on the FIRE FX5019 Module and all industrial control products, backed by professional pre-sales technical consultation (including system design and protocol compatibility checks) and after-sales service (on-site installation support and troubleshooting). If you cannot find the model you need or require customized control solutions for your automation system, contact us immediately:

- WhatsApp: [https://wa.me/+86 19389860630]

- Email: jllucky33@qq.com

Leave a comment

Your email address will not be published. Required fields are marked *