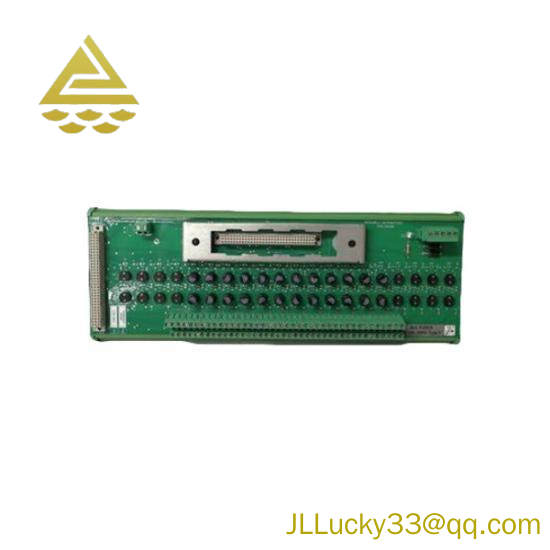

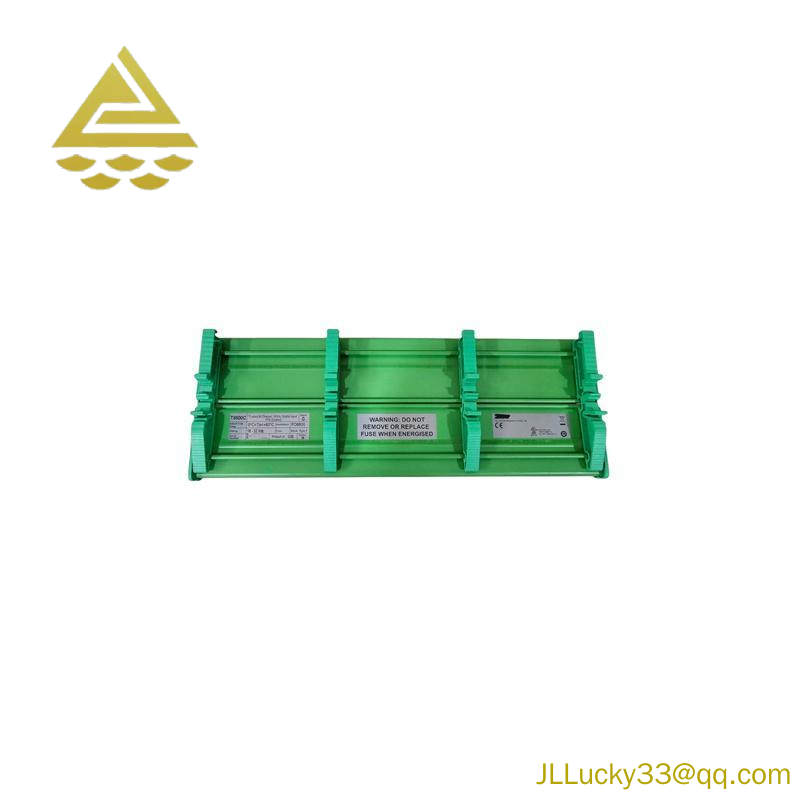

MAGNETEK SUPPLIES GPD515C – B014 INPUT Description

1. Product Introduction

The MAGNETEK SUPPLIES GPD515C – B014 is a crucial component within the GPD515 series of variable frequency drives. This particular unit is designed to handle specific input requirements, playing a fundamental role in ensuring the smooth operation of the overall drive system. It is engineered to be highly adaptable to a range of industrial power sources, making it suitable for diverse applications where precise motor control is essential.

2. Input Specifications

2.1 Voltage Range

The GPD515C – B014 is designed to operate with an input voltage in the range of 380 – 460 VAC. This wide voltage tolerance allows it to be connected to a variety of electrical systems found in industrial settings. Whether in a manufacturing plant with a 400 VAC power grid or a facility operating at 460 VAC, the drive can effectively manage the incoming electrical energy. This flexibility in input voltage is a significant advantage, as it reduces the need for complex voltage conversion systems in many applications.

2.2 Phase and Frequency

It is configured to accept three – phase input power, which is the standard in most industrial power distribution systems. Three – phase power provides a more stable and efficient power supply compared to single – phase, ensuring consistent performance of the drive. The input frequency is compatible with both 50 Hz and 60 Hz power sources, further enhancing its usability across different regions and applications. This ability to work with multiple frequencies makes it a versatile choice for international industrial projects.

2.3 Current Capacity

With a continuous current rating that aligns with its power – handling capabilities, the GPD515C – B014 can manage the electrical load effectively. For instance, in a 7.5 – HP application, it is rated to handle 11 amps continuously at 460 VAC. This current capacity ensures that the drive can provide the necessary power to the connected motor without overloading, even under demanding operating conditions. It also contributes to the drive’s reliability, as it is designed to operate within safe current limits, reducing the risk of component failures due to over – current situations.

3. Significance in Industrial Applications

3.1 Compatibility with Industrial Power Grids

The input characteristics of the GPD515C – B014 make it an ideal choice for integration into existing industrial power infrastructures. In large – scale manufacturing facilities, such as automotive plants or food processing factories, where three – phase power at 380 – 460 VAC is commonly used, this drive can be easily installed without major modifications to the power supply system. Its compatibility with different frequencies also means that it can be used in plants located in regions with different power standards, whether in Europe (50 Hz) or North America (60 Hz).

3.2 Ensuring Stable Motor Operation

A proper input supply is the foundation for stable motor operation. The GPD515C – B014’s ability to efficiently manage the incoming power ensures that the motor receives a clean and consistent electrical supply. This is particularly important in applications where motor speed and torque need to be precisely controlled, such as in conveyor systems, pumps, and fans. By maintaining a stable input, the drive can accurately regulate the output voltage and frequency to the motor, resulting in smooth and reliable operation.

3.3 Reducing Electrical Noise and Interference

In industrial environments, electrical noise and interference can be a significant issue. The GPD515C – B014 is designed to mitigate these problems at the input stage. Its input circuitry is engineered to filter out common – mode and differential – mode noise, preventing it from affecting the performance of the drive and the connected motor. This not only improves the reliability of the motor control system but also reduces the risk of electromagnetic interference with other sensitive equipment in the vicinity.

4. Comparison with Similar Products

4.1 Voltage Tolerance

Compared to some competing variable frequency drives, the GPD515C – B014 offers a relatively wide input voltage range. Some drives may be limited to a narrower voltage band, which can restrict their use in certain industrial settings. The ability of the GPD515C – B014 to operate across 380 – 460 VAC gives it an edge in applications where the power supply voltage may vary slightly or in regions with inconsistent power quality.

4.2 Current Handling Capacity

In terms of current handling, the GPD515C – B014 is designed to handle the typical load requirements of motors in its power class efficiently. While some similar products may have comparable current ratings, the GPD515C – B014’s ability to maintain stable operation under continuous load conditions sets it apart. This is crucial in applications where the motor operates for extended periods, such as in 24/7 manufacturing processes.

4.3 Frequency Compatibility

The drive’s compatibility with both 50 Hz and 60 Hz power sources is also a differentiating factor. Some competing drives may be designed for a single frequency, which can limit their use in international projects or in facilities with a mix of power standards. The GPD515C – B014’s dual – frequency compatibility makes it a more versatile choice for global industrial applications.

5. Conclusion

The MAGNETEK SUPPLIES GPD515C – B014 INPUT is a well – designed component that offers a combination of flexibility, reliability, and performance. Its input specifications, including voltage range, phase, frequency compatibility, and current handling capacity, make it suitable for a wide range of industrial applications. By effectively managing the incoming power, it ensures stable motor operation, reduces electrical noise, and is highly compatible with existing industrial power grids. Compared to similar products, it stands out in terms of voltage tolerance, current handling, and frequency compatibility. Whether used in a small – scale manufacturing unit or a large – scale industrial complex, the GPD515C – B014 can play a vital role in optimizing motor control and overall system performance.

Leave a comment

Your email address will not be published. Required fields are marked *