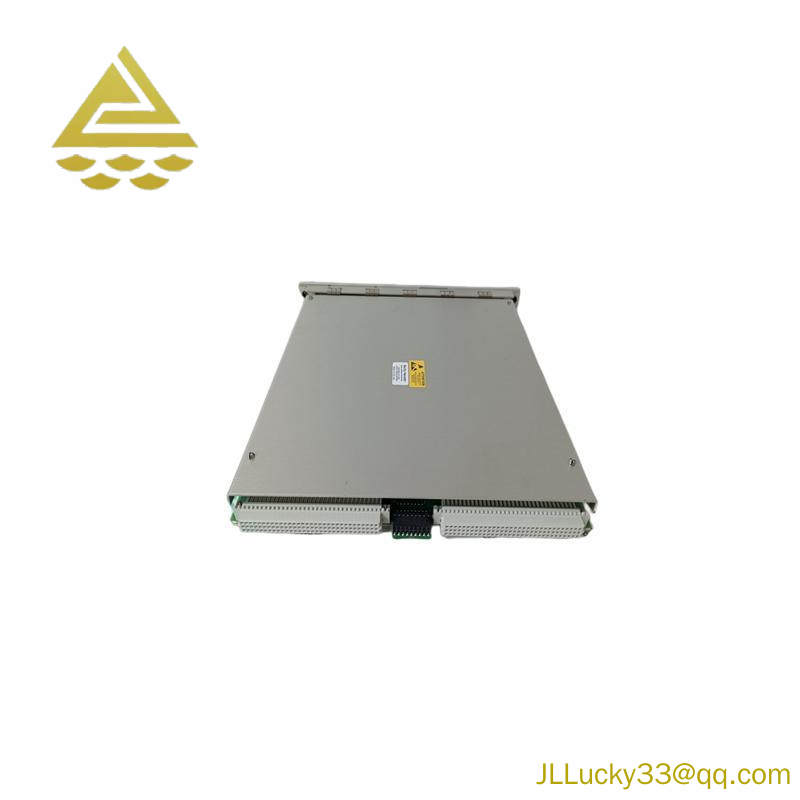

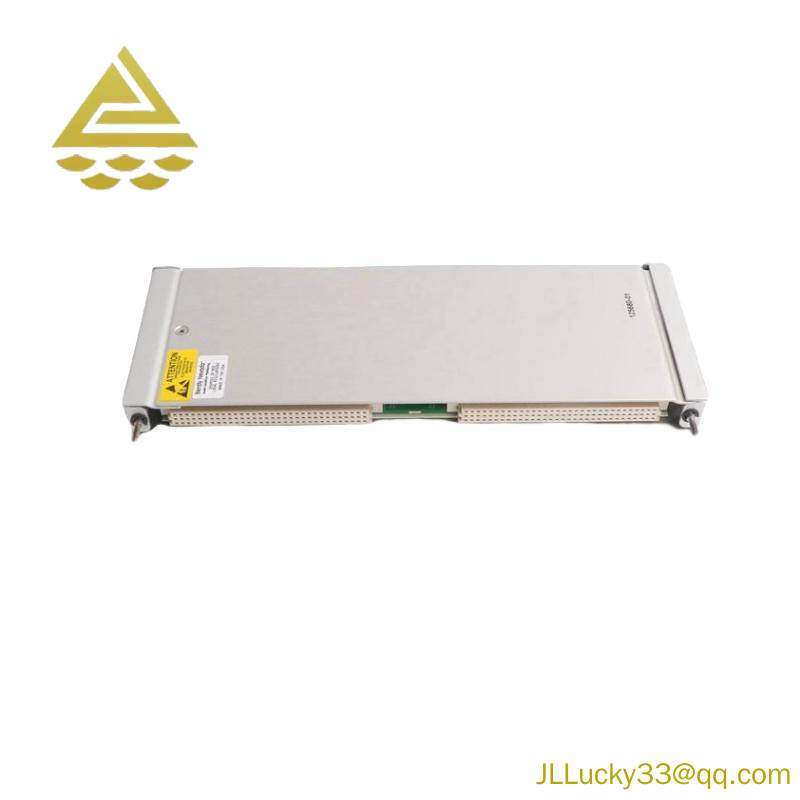

3500/61 133819-02 | vibration monitoring module

Product Overview

The Bently Nevada 3500/61 133819-02 is a precision vibration monitoring module designed for advanced machinery protection and condition monitoring applications. As a core component of the Bently Nevada 3500 Series, the 3500/61 133819-02 delivers reliable and accurate vibration measurements, enabling early detection of machinery anomalies to prevent unplanned downtime. Engineered for high-speed rotating equipment, this module provides continuous, real-time monitoring of vibration velocity, acceleration, and displacement, ensuring optimal machinery performance.

With robust diagnostics, seamless integration capabilities, and industry-leading accuracy, the 3500/61 133819-02 supports a wide range of applications in power generation, petrochemical, and heavy industrial environments. Compact and modular in design, this device facilitates easy installation and maintenance while maintaining compliance with rigorous safety and reliability standards. Hainan Jinlin Mechanical & Electrical is proud to provide this module with a one-year warranty, backed by professional pre-sales and after-sales support.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | 3500/61 133819-02 |

| Manufacturer | Bently Nevada |

| Product Type | Vibration Monitoring Module |

| Power Supply | 24 VDC ±10% |

| Signal Type | AC/DC vibration input |

| Operating Temperature | -40°C to +85°C |

| Mounting | DIN rail / panel mount |

| IP Rating | IP20 |

Key Features and Benefits

High-Precision Monitoring

The 3500/61 133819-02 offers high-fidelity vibration detection for critical rotating machinery, enabling early fault detection and reducing the risk of catastrophic equipment failure. Its wide frequency response and configurable alarm thresholds provide versatile monitoring for various machinery types.

Robust Diagnostics

Equipped with built-in self-diagnostics, this module ensures continuous verification of signal integrity and module functionality. Maintenance teams can quickly identify sensor or wiring issues, minimizing downtime and maintenance costs.

Seamless Integration

Compatible with the 3500 Series monitoring system, the 3500/61 133819-02 integrates effortlessly with other modules, supporting redundant configurations and centralized control. Its standardized outputs and protocols simplify connection to plant control systems and SCADA platforms.

Durable Design

Constructed for harsh industrial environments, this module withstands extreme temperatures, vibration, and electrical noise. Its compact, modular design allows straightforward installation in control panels, optimizing space while maintaining high reliability.

Enhanced Machinery Protection

By providing real-time alerts on vibration anomalies, the 3500/61 133819-02 helps prevent unplanned outages, extend equipment life, and improve overall operational safety.

Related Models

-

3500/60-01-00 – Standard vibration monitoring module compatible with high-speed machinery.

-

3500/61-02-00 – Upgraded version with expanded diagnostic capabilities.

-

3500/50M-01-00 – Companion system module for multipoint vibration monitoring.

-

3500/45-06-00 – Auxiliary relay module for vibration alarm signaling.

-

3500/42-03-00 – Compatible proximity probe module for shaft displacement measurement.

-

3500/33-01-01 – System interface module for integration with SCADA systems.

Hainan Jinlin Mechanical & Electrical provides full technical support and a one-year warranty on the Bently Nevada 3500/61 133819-02. For inquiries or alternative models, contact us via [WhatsApp](https://wa.me/+86 19389860630) or email at jllucky33@qq.com.