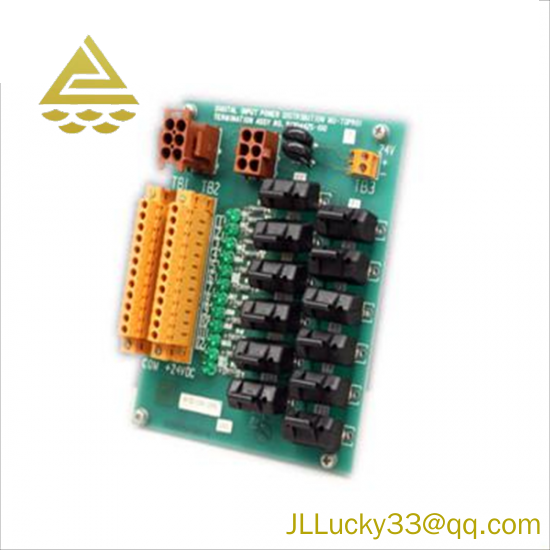

ASSY 11993R2| Assembly Module

Product Overview

The ASSY 11993R2 is a high-performance industrial assembly module designed for reliable integration into demanding automation and control systems. Built with precision engineering and durable components, this module is engineered to deliver consistent functionality in harsh environments, making it a dependable choice for industries such as petrochemical, power generation, and heavy manufacturing.

With its robust design, the ASSY 11993R2 ensures stable operation under continuous workloads while maintaining compatibility with a wide range of system architectures. The module provides enhanced connectivity and seamless integration into both legacy and modern systems, allowing end-users to extend the lifecycle of their installed base. Designed to minimize downtime, it supports fast installation, easy replacement, and optimized performance.

The ASSY 11993R2 stands out for its reliability, compact design, and industrial-grade resilience. Whether used as part of a Distributed Control System (DCS), a Programmable Logic Controller (PLC) network, or other mission-critical control platforms, it provides the stability and assurance needed in high-demand environments.

Hainan Jinlin Mechanical & Electrical is a distributor of industrial control products, specializing in a wide range of brands. We possess extensive industry knowledge and market insights. Adhering to the “Customer First, Forge Ahead” business philosophy, we provide high-quality customer service. We’re here for you, dedicated to meeting your needs!

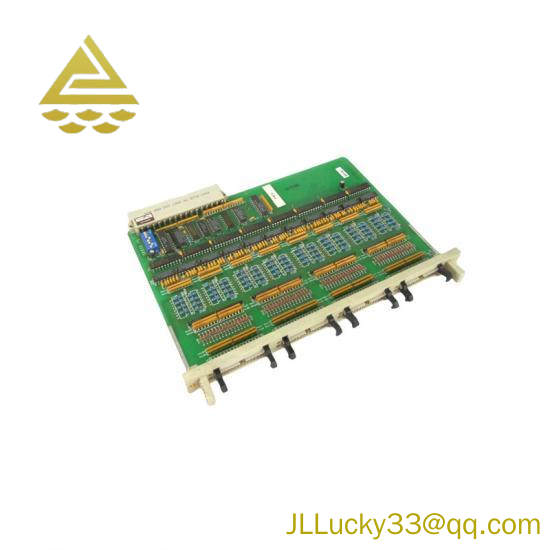

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | ASSY 11993R2 |

| Manufacturer | OEM/Industrial Grade |

| Product Type | Assembly Module |

| Power Supply | 24 VDC (typical) |

| Dimensions | Compact rack-mount |

| Communication | Standard industrial protocol support |

| Operating Temp. | -20°C to +70°C |

| Mounting | Rack or panel mount |

| IP Rating | IP20 (standard) |

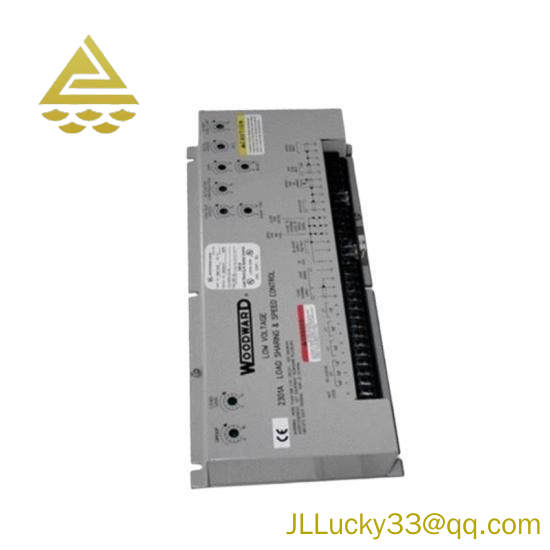

Key Features and Benefits

The ASSY 11993R2 delivers several advantages that make it a preferred solution for automation professionals.

One of its strongest benefits is system compatibility. The module is engineered to integrate seamlessly into existing architectures, enabling users to upgrade or replace components without extensive system modifications. This reduces downtime, lowers engineering costs, and improves overall efficiency.

Durability is another defining feature. The ASSY 11993R2 is designed with industrial-grade components that withstand temperature fluctuations, electrical interference, and continuous operation in harsh industrial environments. Its robust build ensures long service life and reliability.

Ease of use has also been prioritized. Installation is straightforward, and the module supports fast replacement during maintenance cycles, minimizing production interruptions. Integrated diagnostics provide real-time status and fault detection, helping operators quickly identify and resolve issues.

Performance is optimized for modern automation requirements. The module offers stable power handling, efficient communication protocols, and consistent processing performance, ensuring smooth operation even under heavy workloads.

In terms of long-term value, the ASSY 11993R2 provides peace of mind by extending the operational life of critical control systems, protecting customer investments while enabling gradual upgrades. This makes it a cost-effective solution for industries that require stability, resilience, and efficiency in their control platforms.

Related Models

-

ASSY 11993R1 – Previous generation module offering basic functionality.

-

ASSY 11993R3 – Updated version with extended diagnostic capabilities.

-

ASSY 12001R2 – Companion module designed for parallel system integration.

-

ASSY 11877R2 – Alternate assembly unit compatible with similar systems.

-

ASSY 11995R2 – High-performance variant optimized for faster data throughput.

-

ASSY 11993A – Earlier series model commonly used in legacy systems.

-

ASSY 12005R2 – Enhanced model with higher environmental resilience.