GE Fanuc PACSystems RX3i | GE FANUC IC695CPE305

Product Overview

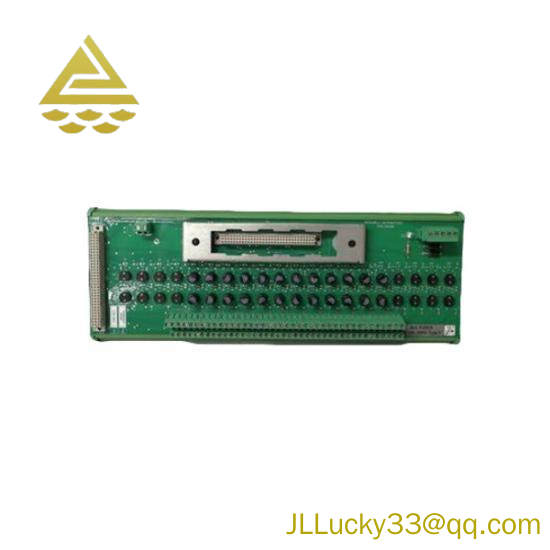

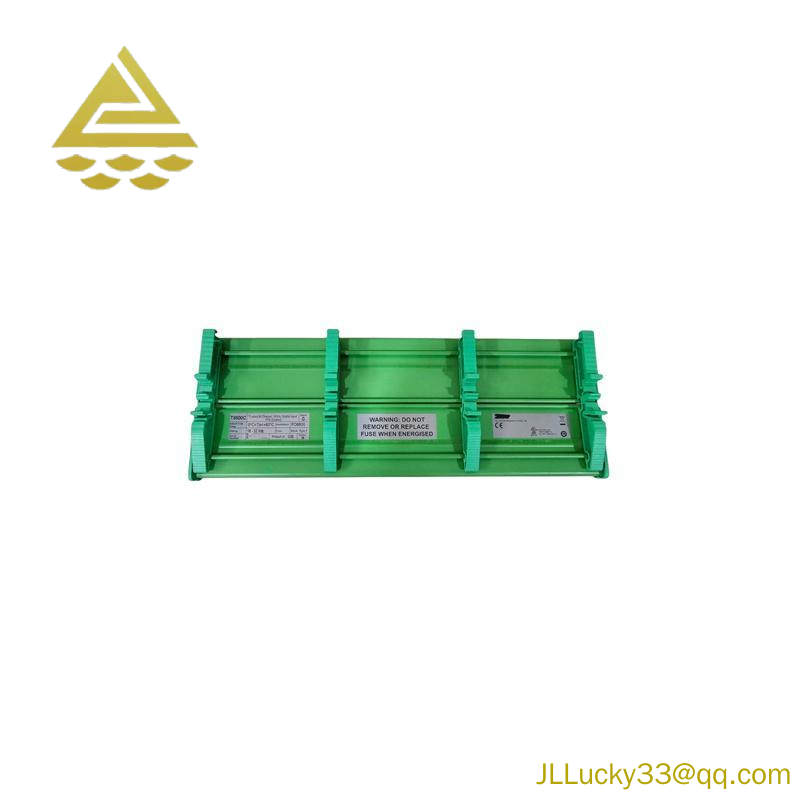

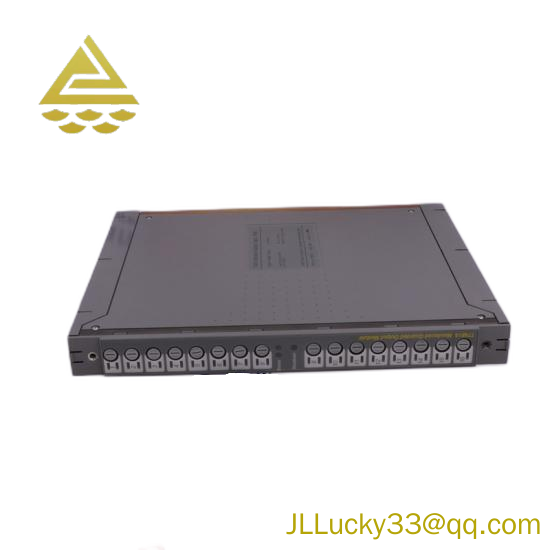

The GE FANUC IC695CPE305 is a high-performance Programmable Automation Controller (PAC) designed as the central processing unit (CPU) for GE Fanuc’s PACSystems RX3i platform—an industry-leading solution for mid-to-large-scale industrial automation. This controller excels in integrating logic control, motion control, and process control into a single, unified system, making it a cornerstone for industries such as automotive manufacturing, power generation, and water/wastewater treatment. Key features of the GE FANUC IC695CPE305 include a 1.0 GHz dual-core processor for fast data processing, support for up to 32 I/O modules, and built-in cybersecurity protocols to protect industrial networks. Whether deployed in factory automation lines, power plant auxiliary systems, or municipal water facilities, the GE FANUC IC695CPE305 delivers reliable, real-time control—critical for industries where operational continuity and process precision directly impact productivity and safety.

Hainan Jinlin Mechanical & Electrical is a distributor of industrial control products, specializing in a wide range of brands. We possess extensive industry knowledge and market insights. Adhering to the “Customer First, Forge Ahead” business philosophy, we provide high-quality customer service. We’re here for you, dedicated to meeting your needs!

Technical Specifications

|

Parameter

|

Value

|

|

Product Model

|

GE FANUC IC695CPE305

|

|

Manufacturer

|

GE Fanuc (now part of Emerson PACSystems)

|

|

Product Type

|

PAC (Programmable Automation Controller) – CPU Module

|

|

Compatible Platform

|

GE Fanuc PACSystems RX3i

|

|

Processor

|

1.0 GHz Dual-Core ARM Cortex-A9

|

|

Memory

|

1 GB DDR3 RAM; 4 GB Flash Storage

|

|

I/O Capacity

|

Supports up to 32 RX3i I/O Modules

|

|

Operating Voltage

|

5 V DC (powered via RX3i backplane)

|

|

Operating Temperature

|

0°C to +60°C (32°F to +140°F)

|

|

Communication Protocols

|

Ethernet/IP, Modbus TCP, PROFINET, DNP3

|

|

Cybersecurity Features

|

Role-Based Access Control (RBAC), Secure Boot, TLS 1.3

|

|

Mounting Type

|

PACSystems RX3i Chassis Backplane Mount

|

|

IP Rating

|

IP20 (chassis-protected, suitable for control cabinets)

|

Key Features and Benefits

The GE FANUC IC695CPE305 stands out as a versatile and robust PAC solution, addressing core challenges of integrated automation in complex industrial environments while delivering measurable operational value.

High-Speed Processing for Real-Time Control

Powered by a 1.0 GHz dual-core ARM Cortex-A9 processor, the GE FANUC IC695CPE305 executes control logic, processes I/O data, and handles communication tasks with minimal latency. It achieves a logic scan time of less than 1 ms for 10,000 boolean instructions—critical for time-sensitive applications like automotive assembly line robotics, where synchronized motion control and sensor feedback are essential. The dual-core design also enables parallel processing: one core manages real-time control, while the other handles non-critical tasks (e.g., data logging, HMI communication), ensuring no compromise on control performance.

Scalable I/O and System Expansion

The GE FANUC IC695CPE305 supports up to 32 RX3i I/O modules (analog, digital, specialty), allowing it to adapt to diverse application needs—from small-scale machine control (e.g., a single packaging line) to large-scale plant-wide automation (e.g., a multi-unit power plant). It also integrates seamlessly with GE Fanuc’s motion control modules (e.g., IC695MDR390) and process control modules (e.g., IC695PBM300), eliminating the need for separate controllers. This scalability reduces hardware costs and simplifies system architecture, making it easier for operators to manage and maintain.

Built-In Cybersecurity for Industrial Networks

In an era of increasing cyber threats to industrial systems, the GE FANUC IC695CPE305 includes robust security features to protect critical automation data. It supports Role-Based Access Control (RBAC) to restrict unauthorized configuration changes, Secure Boot to prevent malware from loading during startup, and TLS 1.3 encryption for communication with HMIs, SCADA systems, and cloud platforms. These features ensure compliance with industry standards like IEC 62443, safeguarding against cyberattacks that could cause production downtime or safety hazards.

Seamless Integration with Legacy and Modern Systems

The GE FANUC IC695CPE305 is backward-compatible with older GE Fanuc Series 90-30 I/O modules, allowing facilities to upgrade their CPU without replacing existing I/O infrastructure—a significant cost-saving advantage for plants with legacy systems. It also supports modern industrial protocols (Ethernet/IP, PROFINET) for integration with third-party devices (e.g., Siemens VFDs, Allen-Bradley HMIs) and cloud platforms (e.g., Emerson’s Plantweb Optics) for remote monitoring and predictive maintenance. This flexibility ensures long-term usability, even as industrial automation technologies evolve.

Rugged Design for Industrial Reliability

Built to GE Fanuc’s strict industrial standards, the GE FANUC IC695CPE305 operates reliably in harsh control cabinet environments. Its wide operating temperature range (0°C to +60°C) accommodates typical factory and plant conditions, while resistance to electrical noise (via built-in EMI filtering) prevents interference from nearby motors or high-voltage equipment. The module’s backplane-mounted design also reduces wiring complexity and minimizes the risk of loose connections, further enhancing operational reliability.

Related Models

- GE FANUC IC695CPE310 – Enhanced version of the GE FANUC IC695CPE305 with a 1.2 GHz quad-core processor and 2 GB RAM, ideal for large-scale process control applications (e.g., petrochemical refineries).

- GE FANUC IC695CPE205 – Entry-level variant of the GE FANUC IC695CPE305 with a 800 MHz single-core processor and 512 MB RAM, designed for small-to-mid-scale automation (e.g., food processing lines).

- GE FANUC IC695CPE306 – Redundant CPU module paired with the GE FANUC IC695CPE305 for safety-critical applications (e.g., nuclear power plant auxiliary control), ensuring zero downtime during CPU failures.

- GE FANUC IC695CPE305-S – Safety-certified model of the GE FANUC IC695CPE305 (SIL 2/PL d compliance), suitable for applications requiring functional safety (e.g., emergency shutdown systems in chemical plants).

- GE FANUC IC695CPE305-W – Wireless-enabled variant of the GE FANUC IC695CPE305 (Wi-Fi 6, 5G), designed for remote or hard-to-reach installations (e.g., offshore oil platform control systems).

- GE FANUC IC695CPE305-E – Extended-temperature model of the GE FANUC IC695CPE305 (-20°C to +70°C), optimized for extreme environments (e.g., arctic pipeline monitoring, desert solar farms).

- GE FANUC IC695PBM300 – Process bus module that pairs with the GE FANUC IC695CPE305, enabling integration with IEC 61850-compliant devices (e.g., smart meters in power distribution systems).

- GE FANUC IC695MDR390 – Motion control module compatible with the GE FANUC IC695CPE305, adding support for up to 8 axes of motion (e.g., robotic arm control in automotive assembly).

Company Expertise & Warranty

As a certified partner of industry leaders such as Bentley Nevada, Honeywell, and GE Fanuc (Emerson PACSystems), we provide key components for process industries, discrete manufacturing, and infrastructure projects. Our team offers specialized pre-sales support for the GE FANUC IC695CPE305—including compatibility checks with existing RX3i systems, I/O module selection, and cybersecurity configuration—and comprehensive after-sales service, such as on-site installation, firmware updates, and technical training. All products, including the GE FANUC IC695CPE305, come with a one-year warranty to cover manufacturing defects and performance issues.

If you cannot find the model you need, please contact us immediately.

Contact Information

- WhatsApp: [https://wa.me/+86 19389860630](https://wa.me/+86 19389860630)

- Email: jllucky33@qq.com

Typical Application Areas

- Automotive Manufacturing: Control of assembly line robotics (using the GE FANUC IC695CPE305 to synchronize robotic welding, painting, and material handling) and quality inspection systems (processing data from vision sensors to detect defects).

- Power Generation: Management of auxiliary systems in thermal power plants (e.g., boiler feedwater control, ash handling) and integration with SCADA systems for real-time load balancing.

- Water/Wastewater Treatment: Regulation of pump stations, chemical dosing systems, and filtration processes (using the GE FANUC IC695CPE305 to maintain water quality compliance and optimize energy usage).

- Chemical & Petrochemical: Control of batch processes (e.g., polymer production) and continuous processes (e.g., distillation columns), leveraging the controller’s high-speed processing to ensure precise temperature and pressure regulation.

- Food & Beverage: Automation of packaging lines and pasteurization systems, where the GE FANUC IC695CPE305’s scalability supports multiple production lines and its reliability minimizes downtime in 24/7 operations.